The Low Expansion Composite, or LXG, is a very useful construction material used in making reinforced plastics. It is especially useful in the area of reinforcing steel beams. The name Low Expansion is due to the fact that the core component of this composite does not expand significantly when heated to nearly near zero cesium. The low expansion feature of the core allows for the use of the LXG in building structures that would otherwise be difficult if not impossible to make with standard composites.

Engineers prefer to use Low Expansion composite because they are more flexible. These composites have the ability to expand and contract without any significant loss of strength over the length of their useful life. These types of materials are also more resistant to corrosion from both mild acids and alkalis. Many of these composites can also handle temperature fluctuations and can be insulated from temperature changes in the atmosphere. While standard composites cannot withstand sudden temperature fluctuations or extreme temperatures, the low-expansion ones can handle both conditions.

Typically, these materials are used in the construction of reinforced plastics or metal frames. The main advantages of using these composites in construction are: they are more durable and much more affordable than steel. They are also safer to work with and easier to install than traditional steel framing. They offer a variety of options in the core options that are available for installation.

There are two major components of LXG composites, which determine the strength and the expansion ratio. These components are the carbon fiber (or CTF) and the vanadium (VCT). When these two materials are mixed with each other, the resulting material has a higher carbon content and a lower vanadium content. The greater amount of carbon and less vanadium in the core leads to a greater amount of strength, but it also tends to produce a weaker overall strength comparison to other standard composites.

The low-expansion ratio is an important part of the strength equation, as it determines the fatigue life of a product. It is measured in carat per square inch. A high expansion ratio will result in a thicker frame, which requires a larger and thicker core. The more expensive frames may have the ability to handle larger carats, but this is a matter of personal choice. A high or low expansion ratio will be related to both the grade and the size of the core as well as the manufacturing process used to create the frame.

Many composites are available in multi-wall thicknesses. These allow many different core materials to be utilized. Some are also made to be as light as possible. It should be noted that this would affect both the cost and the strength of the finished structure.

The high-molded options are the most popular, as they allow for customization in terms of both the shape and the core. The core can be made from low-density composites or thermoplastic polymers. The thermoplastic core allows for flexibility during the molding process, as it is not tied down by crystalline growth. This makes it possible to change the core density, length and depth as required without changing the structural shape.

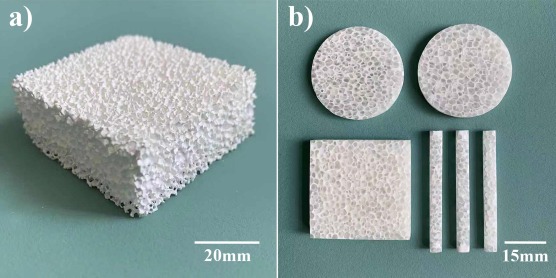

Low-density foam core designs are available in both closed-cell and open-cell designs. The closed cell design is used when a greater amount of material is needed to create the same weight, thickness and hardness rating as a high-density foam. The open cell design uses various additives that can control the internal temperatures of the core. The combination of these two creates an expandable design, which is then molded into a metal or steel frame. The material will settle at a predetermined temperature, depending on the application, and then harden once fully hardened.