A ferromagnetic material possesses the ability to resist the effects of heat and pressure. This makes them ideal for use in applications where durability and resistance to heat and pressure are important factors, such as in magnetic storage devices and brakes. They are also used in parts of cars that interact with magnets, such as the suspension system.

Types of Ferromagnetic Material

There are a variety of types of ferromagnetic material that can withstand the most heat and pressure. The most common type is iron, which can be found in everything from kitchen appliances to train tracks. Other common types include nickel-based alloys, cobalt-based alloys, and manganese-based alloys. Each of these materials has its own unique properties that make it ideal for specific applications.

One of the main benefits of using ferromagnetic materials is their ability to resist corrosion. This is thanks to the magnets’ strong magnetic fields, which keep metal ions from bonding with each other and forming deposits on the material’s surface. They also tend to be lightweight and easy to work with, making them well-suited for applications where weight or portability are important factors.

Finally, they are capable of dissipating a lot of heat energy compared to other types of materials. This property makes them perfect for applications where high temperatures are required, such as in nuclear power plants or steel mills. By understanding which type of ferromagnetic material is best suited for a given application, you can avoid potential problems down the road.

How Heat and Pressure Affect Ferromagnetic Materials?

When it comes to heat resistant materials, ferromagnetic materials are some of the best options. This is because they have a higher thermal conductivity. This means that they can transfer heat more efficiently than other materials. This makes them resistant to high heat and pressure environments.

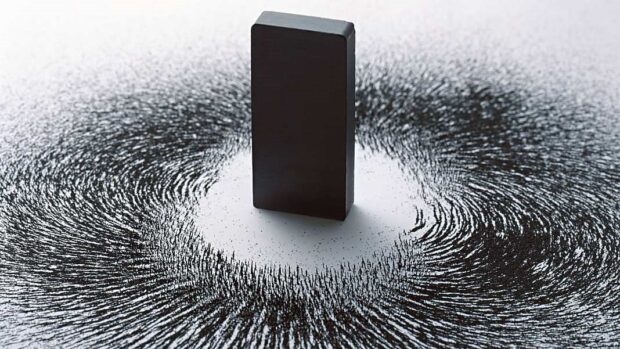

One reason ferromagnetic materials are so resistant to heat and pressure is because the electron spins tend to remain aligned even when heated or compressed. This property is called thermal stability and it accounts for why these materials are so good at withstanding high temperatures and pressures. In fact, ferromagnetic materials are some of the most thermally stable materials available and they can often maintain their properties after being subjected to extreme conditions.

How to Protect Your Material from Heat and Pressure?

There are a few ways to protect your material from heat and pressure. The most common way is to use a material that can tolerate high temperatures and pressures, such as metal or plastic. Another way is to use insulation, which will help to keep the material cool.

It is also important to make sure that the material you are using can handle the high temperatures and pressures that are involved in a manufacturing process. If you are using a material that is not typically used in manufacturing, you will need to test it before you start the project to make sure that it can handle the heat and pressure.

Conclusion

In this article, we are going to be discussing what materials can withstand the most heat and pressure. We will be looking at a few different types of metals and plastics, and explaining which ones are the best for various applications.