If you are working in the substance and cycle fabricating industry, you know how significant Safety Data Sheets (SDSs) are to your business. They give urgent data about the well-being and treatment of perilous synthetic substances and assist you with remaining consistent with unofficial laws.

Overseeing SDSs physically isn’t just time-and work concentrated; it’s blunder inclined — compromising consistency alongside laborers’ and buyers’ well-being. So let’s know what Safety Data Sheets are all about in our 2024 guide.

What To Know About The Program Of Safety Data Sheets?

Safety Data sheet programming helps organizations make and disperse required documentation on the properties, dangers, and well-being insurance for taking care of, putting away, and moving dangerous synthetic compounds. In addition, every synthetic should have an SDS to maintain consistency with the U.S. Word-related Safety and Health Administration (OSHA) and other worldwide administrative bodies.

For What Reason Is SDS Significant?

While working with dangerous synthetic substances, well-being and security data must be promptly open if there should arise an occurrence of a mishap or spill; laborers have very little time looking for emergency treatment data. That is why administrative offices require an SDS to be made for and put away with each risky synthetic your organization produces and circulates.

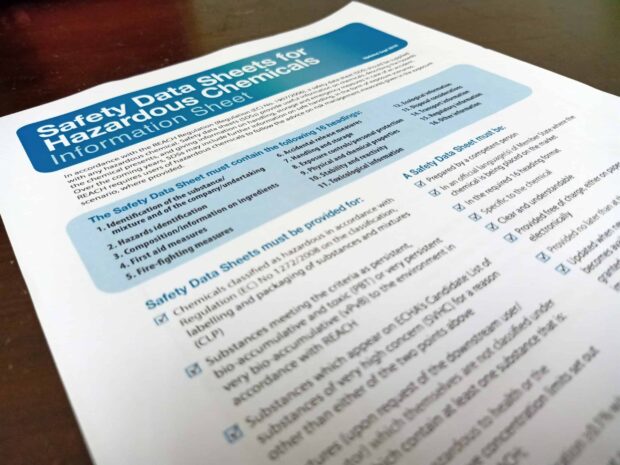

Every SDS must distinguish:

- What the compound is.

- The well-being, security, and ecological perils, like consuming skin, harming eyes, or polluting water.

- The most effective method to contain and store the synthetic to forestall these dangers.

- The reaction if any mishap occurs, for example, pouring water on a spill or medical aid data while treating a burned skin.

In 2015, OSHA changed its Hazardous Communication Standard (known as OSHA HazCom 2015) to make it a worldwide norm for SDSs in an undeniably globalized economy. Like the by and large global images utilized at crosswalks and on washroom signs, the objective was to make steady documentation for laborers all over the planet who may not know how to deal with synthetic substances that can present serious dangers.

This documentation is demanded each time you make and sell another synthetic compound. In addition, an SDS cautions individuals on how the item should be taken care of and treated, which accompanies a great deal of risk — if you advise somebody to treat fire with water. Yet, water makes the fire deteriorate; then, at that point, your organization could be considered liable for the unfortunate results. Click here and know more.

That is why SDSs are essential to get right — and why these records are so definite. All of them are 16-section reports. In addition, associations may not know when they’re resistant, making OSHA HazCom the second-most normal infringement after Fall Protection.

How Does SDS Programming Work?

There are various ways of dealing with the convoluted SDS process: Some organizations get their on-staff physicists to deal with it; others re-appropriate the entire thing to an outsider. However, the most effective and reasonable way is to utilize programming.

The experts currently have SDS writing abilities that can make an SDS for you utilizing shrewd rationale. Finally, the product takes a gander at the plan to deliver an item, distinguishing every fixing down to the CAS number and giving basic data on everyone.

For instance, say you’re making paint containing colors, covers, solvents, and substances. First, you’ll need to demonstrate whether these are natural substances or, on the other hand, assuming that the actual fixings are mixes of various base synthetic compounds, taking a gander at the Chemical Abstract number (CAS number; a general standard that characterizes based synthetic substances).

When you separate the definition to the imperative CAS numbers and know the level of everyone, the product assumes control over it, utilizing rationale to think about every synthetic against standard industry information bases, like LOLI and Chemwatch. These global data sets, coordinated by CAS number and nation, let you know all of the difficult properties for every crude synthetic in your plan.

Outfitted with this data and the rates in the completed item you’ve provided, the product does the math — assisting you with populating key segments of the SDS.

How Does SDS Programming Keep You Consistent?

SDS composing programming helps with remaining consistent with OSHA HazCom 2015, protecting specialists and clients while keeping away from expensive fines. This product does a large part of the work for you, guaranteeing exactness while saving time and exertion, working on your main concern.

Here is a portion of the critical segments of the SDS that professionals assist you with finishing:

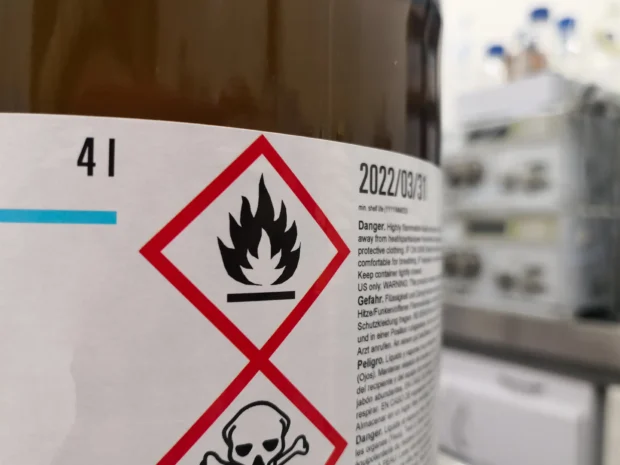

Segment Two: Hazard(s) Identification

As the term indicates, this section contains all the potentially dangerous information associated with each synthetic. In addition, it includes a symbol that indicates how perilous the substance is. There are two codes next to the pictogram:

- Prudent codes (P codes, or P articulations) list the well-being and security measures to follow to limit risk (i.e., “abstain from relaxing,” “wash skin completely upon contact”).

- Danger codes (H codes, or H articulations) list the dangers related to the synthetic (i.e., “destructive whenever gulped,” “causes skin aggravation”).

The pictogram, P codes, and H codes are still up in the air by looking at the CAS number against the public authority guidelines set by HazCom 2012, known as the “Purple Book,” utilizing the previously mentioned worldwide data sets for confirmation.

Sorting this out would take a lot of human labor, as well as knowledge of the criteria and a thorough understanding of the component estimates — but all SDS programming takes care of everything for you. It seamlessly completes the sections in your SDS’s second segment, which a scientist may evaluate.

Segment Three: Ingredients/Composition/Information

This segment contains data about every compound fixing, posting the level of each perilous base synthetic and its CAS number. For instance, assuming that a detailing contains 5% benzene, segment three would list every constituent thing in that compound. This part additionally incorporates proprietary innovation claims.

Segments Four and Five: Measures for First Aid and Firefighting

Here, the list of significant well-being and security data will be included, along with intense and deferred side effects and impacts of substance openness, required therapies, appropriate fire-quenching strategies and hardware, and compound perils in the event of a fire.

For the medical aid and firefighting segments, SDS composing devices can assist you with saving time and exertion by making a layout for every one of your organization’s product offerings. These formats permit you to choose from drop-downs of normal reaction measures, for example, “counsel a doctor” or “flush completely if contact is made with eyes.” In addition, when you foster comparative items, these layouts can be generally reused across product offerings.

Segment Nine: Physical and Chemical Properties

This part records every substance’s qualities and incorporates data, for example, the limit and glimmer points. Here, the product can make estimations in light of the fixings recorded and their properties.

To stay consistent, these names should go on each item once delivered, regardless of whether it’s a little example or you’re charging for it. Making marks for every one of these examples, particularly in organizations with a high item detailing volume, can get costly rapidly while utilizing manual strategies. Yet, experts produce the comparing name stickers, including the legitimate pictogram and codes, each time you make an SDS.

Bottom Line

Compound and interaction-producing organizations lack the opportunity and energy to squander SDSs and names physically. Perceive how much better it tends to be with professional SDS composing capacities and pursue a free demo today.